DEPARTMENT oF ENVIRONMENT & FOREST

Andaman & Nicobar Administration

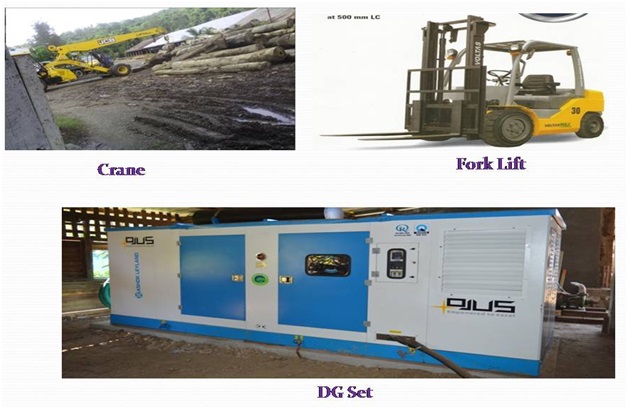

The Govt. Saw Mill, Betapur is one of the two Govt. Saw Mill in Andaman & Nicobar Islands established in the year 1955-56. It is located in Betapur Range of Middle Andaman Forest Division. It has got installed capacity to intake 5000 Cbm of round logs. It has got facility to treat timber as per directions of Hon'ble Supreme Court. It has been upgraded with aim to increase capacity of intake of logs to 12,000 Cbm, increase percentage outturn, improve infrastructure in terms of buildings & machinery to make all record keeping computerized and improve transparency in allotment of timber.